- Part Detail

- CLICK TO VIEW

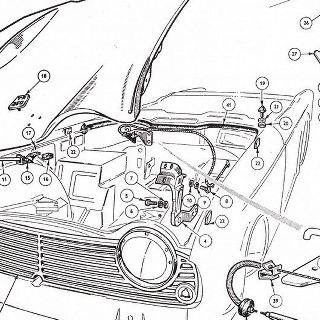

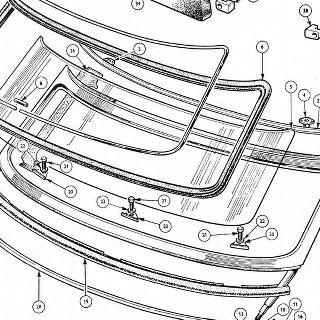

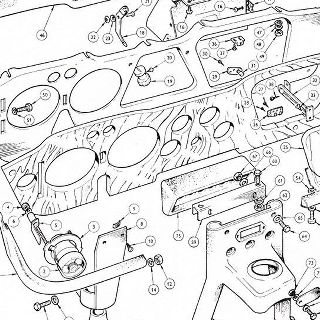

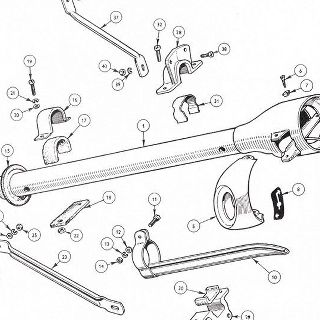

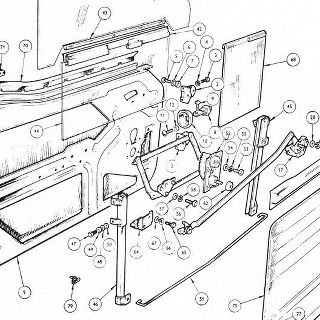

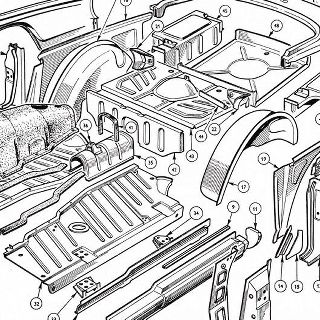

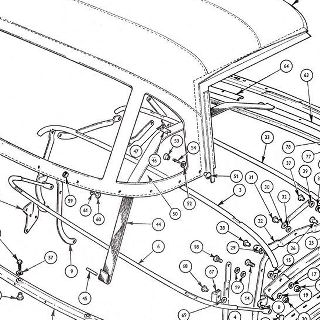

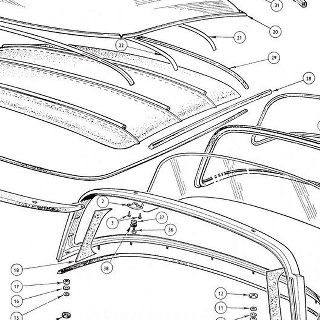

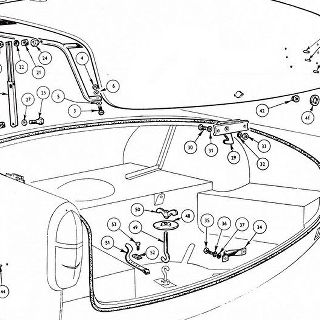

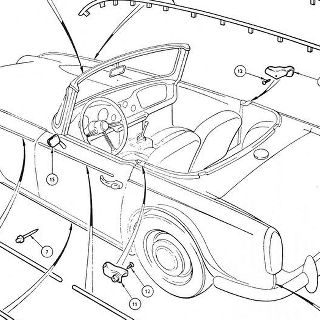

TRIUMPH PLATES - Browse Original Triumph Catalogue Plates

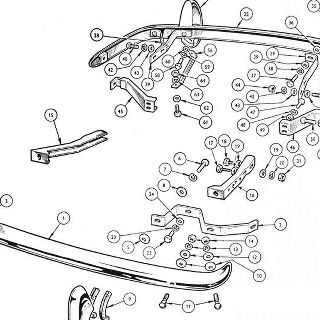

BOOT HINGE TR3-3B CHROME PLATED PR HIGH QUALITY

Part No:

650023HQK

Price

£163.09

Price Ex VAT @ 20%

£135.91

IN STOCK This part is immediately available

Boot Hinge pair chrome plated high quality gravity die cast fitted to the TR3 from TS8637 (the beginning of TR3 production to end of TR3B production).

In addition to the standard range of bonnet and boot hinges for TR2-3B, Revington TR offer this higher quality range, gravity die cast in ZA27 aluminium-zinc alloy which has similar strength and corrosion resistive properties as Gun Metal.

These hinges are very strong, being gravity die cast and incorporate stainless steels hinge pins; a little extra cost, but worth it in the long run.

These hinges will not corrode to look like a 'blue cheese' as will certainly happen with a pressure die cast product. The difference is immediately obvious in the weight, the gravity die cast product being heavier as the material is dense and therefore strong. Pressure die casting produces a lighter product with an outer skin containing a sponge like interior. This makes it weak and likely to snap at the hinge point if overstressed. These hinges are difficult to restore too as the material corrodes like a 'blue cheese'.

The stainless steel pin which itself will not corrode, is held in a perfectly sized hinge pivot hole ensuring the bonnet(hood) or boot panel is held firmly. As the gravity die cast material these hinges are made from is strong and corrosion resistive, the hinge point will stay in good condition for many years. In contrast the loose pins found in the pressure die cast product produces an irritating panel rattle that is particularly obvious (and irritating) at idle. As the material is highly prone to corrosion the hole in which the pin sits will quickly corrode leaving an oval hole for the pin to rattle in even if the pin was tight when new.

In addition, as the material is dense and strong the attachment studs will be held tight with no danger of them being pulled out of the casting when the nuts are tightened on installation to the correct torque. Quite the opposite is the case with the cheaper pressure die cast product as it is quite common for the studs to pull out on installation. If this should happen the only solution is to throw the hinge away and replace it.

Our high quality hinges are sold individually and in pairs, each hinge coming with the appropriate studs nuts and washers. Please see below

The chrome finish on these hinges is to the highest standard. After polishing the hinge bodies are subjected to a 4 stage plating process; two stages of copper plate, then nickel plate followed by the final chrome plate. This lengthy (and costly) process ensures the chrome surface will stay in good condition for many years.

Important Note:-These hinges are handed so ensure you fit them to the correct side. Incorrect fitment will lead to body distortion as the hinge tries to twist the wrong way.

These hinges are very strong, being gravity die cast and incorporate stainless steels hinge pins; a little extra cost, but worth it in the long run.

These hinges will not corrode to look like a 'blue cheese' as will certainly happen with a pressure die cast product. The difference is immediately obvious in the weight, the gravity die cast product being heavier as the material is dense and therefore strong. Pressure die casting produces a lighter product with an outer skin containing a sponge like interior. This makes it weak and likely to snap at the hinge point if overstressed. These hinges are difficult to restore too as the material corrodes like a 'blue cheese'.

The stainless steel pin which itself will not corrode, is held in a perfectly sized hinge pivot hole ensuring the bonnet(hood) or boot panel is held firmly. As the gravity die cast material these hinges are made from is strong and corrosion resistive, the hinge point will stay in good condition for many years. In contrast the loose pins found in the pressure die cast product produces an irritating panel rattle that is particularly obvious (and irritating) at idle. As the material is highly prone to corrosion the hole in which the pin sits will quickly corrode leaving an oval hole for the pin to rattle in even if the pin was tight when new.

In addition, as the material is dense and strong the attachment studs will be held tight with no danger of them being pulled out of the casting when the nuts are tightened on installation to the correct torque. Quite the opposite is the case with the cheaper pressure die cast product as it is quite common for the studs to pull out on installation. If this should happen the only solution is to throw the hinge away and replace it.

Our high quality hinges are sold individually and in pairs, each hinge coming with the appropriate studs nuts and washers. Please see below

The chrome finish on these hinges is to the highest standard. After polishing the hinge bodies are subjected to a 4 stage plating process; two stages of copper plate, then nickel plate followed by the final chrome plate. This lengthy (and costly) process ensures the chrome surface will stay in good condition for many years.

Important Note:-These hinges are handed so ensure you fit them to the correct side. Incorrect fitment will lead to body distortion as the hinge tries to twist the wrong way.